Ubah Bahasa :

Sistem suplai energi dan bantalan untuk mesin cetak injeksi

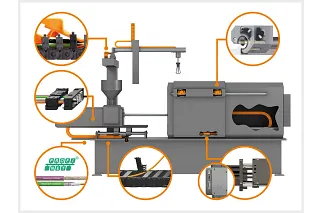

Di tempat tidur mesin, di unit injeksi, di unit penjepit, dan dalam penanganan: sistem rantai energi kami, kabel yang sangat fleksibel, dan teknologi bantalan bebas perawatan memastikan masa pakai yang lama di semua unit yang bergerak pada mesin cetak injeksi plastik Anda.

Desain khusus kabel chainflex® kami dengan inti penghilang regangan, bundle stranding dan selubung luar PVC atau TPE sangat ideal untuk aplikasi yang sangat dinamis, seperti unit penjepitan dengan gerakan yang sering dan waktu siklus yang pendek. Rantai elektronik kami® memastikan perutean bundel kabel yang aman. Desainnya dicirikan oleh pemasangan yang sederhana, cepat, dan interior yang ramah kabel - sangat menarik ketika menggunakan selang hidrolik. Selain dimensi kecil untuk ruang instalasi kecil, panjang yang tidak didukung dan beban tambahan juga dimungkinkan. Produk bantalan kami yang terbuat dari berbagai macam bahan mendapatkan poin untuk bobotnya yang rendah dan bebas dari korosi dan pelumasan, seperti pemandu linier drylin®, yang memastikan, misalnya, bahwa pintu pengaman unit penjepit meluncur dengan mulus.

Produk untuk digunakan dalam mesin cetak injeksi

Keuntungan dari rantai elektronik polimer

Beban tambahan yang tinggi, akurasi, dan suhu tinggi merupakan faktor penting saat memasok energi ke mesin plastik. Rantai energi plastik kami memastikan pemanduan kabel dan selang yang aman dan juga menunjukkan keunggulannya dengan beban berat:

- Memungkinkan beban tambahan yang tinggi

- Memungkinkan gerakan melingkar dan berputar

- Digunakan pada suhu tinggi

- Tahan terhadap debu, endapan serbuk dan kelembapan

- Desain hemat ruang

Dengan solusi otomatisasi yang hemat biaya dan plastik pintar, kami juga membahas topik utama integrasi sistem dan industri plastik 4.0.

Berhasil digunakan

Penanganan & Otomasi

Saat memasukkan bahan, mengeluarkan bagian cetakan dan sariawan yang sudah jadi dan memasukkannya ke dalam cetakan: ada berbagai proses penanganan di sekitar mesin cetak injeksi plastik yang kami tawarkan produk otomasi hemat biaya. Produk ini memudahkan proses otomatisasi untuk diadaptasi dan investasi akan terbayar dengan sendirinya hanya dalam beberapa bulan.

Informasi lebih lanjut

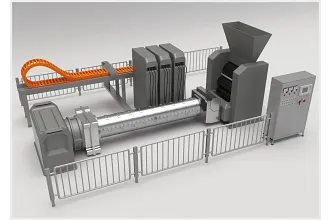

Mesin ekstrusi

Komponen yang tahan media dan bebas pelumasan untuk pengekstrusi, peracik, dan lain-lain.

Cari tahu selengkapnya sekarang

kabel chainflex®

Masa pakai yang tinggi dalam aplikasi bergerak

Cari tahu selengkapnya sekarangKonsultasi

Saya akan dengan senang hati menjawab pertanyaan Anda secara langsung

PT igus® Indonesia+62 21 7588 1933Tulis e-mail

Pengiriman dan konsultasi

Secara pribadi:

Senin - Jumat dari jam 8.30 - 17.30 WIB

Online:

24 Jam

WhatsApp-Service:

Senin - Jumat dari jam 8.30 - 17.30 WIB