Ubah Bahasa :

Components for hygiene-sensitive areas in the food industry

Use of igus® products in the food industry

Selected motion plastic for the food industry

.

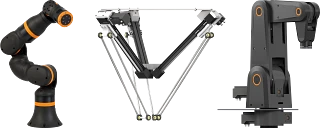

Cobot, pemetik delta, robot lengan gel, dan banyak lagi ...

Otomasi dalam industri pengemasan

Mengotomatiskan proses dengan kompleksitas rendah, integrasi cepat ke dalam sistem yang ada, dan pengembalian investasi yang cepat? Itulah tujuan yang dinyatakan dari produk kami dari "Low Cost Automation".

Penyesuaian format dalam industri pengemasan - dari manual hingga pemosisian cerdas

.

Successful in use

Aggressive environmental conditions (cleaning, extreme temperatures, dust and dirt), high hygiene standards, long service life in continuous operation, fast and flexible format adjustments... The requirements in the packaging, food and beverage industries are diverse. Here you can find out more about the successful use of our motion plastic by our customers.

.

whitepaper: Kolsterisasi dan tribopolimer

Khususnya dalam industri yang bergantung pada pemrosesan yang tepat dan cepat dengan kemurnian dan keekonomisan maksimum, kombinasi kolsterisasi dan plastik berkinerja tinggi harus menjadi standar...

Tested for real use in the test laboratory

iglidur® bearings and drylin® linear technology are put through their paces in the industry's largest plastic test laboratory. Among other things, they are tested for media resistance (e.g. cleaning media), continuous load and low-noise operation. The results are fed into our tools for calculating service life and enable precise predictions to be made about durability.

Upon request, igus® also carries out customer tests in order to test the use of the products under very individual conditions.

Informasi lebih lanjut

.

The large sample box

With the igus® corner, you always have the right motion plastic for your industry at your fingertips.

.

igus® blogs

Topik dan tren dari industri pengemasan. Temukan mereka sekarang di blog kami.

Konsultasi

Saya akan dengan senang hati menjawab pertanyaan Anda secara langsung

PT igus® Indonesia+62 21 7588 1933Tulis e-mail

Pengiriman dan konsultasi

Secara pribadi:

Senin - Jumat dari jam 8.30 - 17.30 WIB

Online:

24 Jam

WhatsApp-Service:

Senin - Jumat dari jam 8.30 - 17.30 WIB