Ubah Bahasa :

laboratorium uji igus®: penelitian seluas 5,500m²

Terbukti, dapat diprediksi, teruji

.

Tech up, cost down - di igus® kami memproduksi bahan dan produk kami sesuai dengan moto ini. Hal ini menawarkan masa pakai yang lama, yang memperpanjang masa pakai mesin dan aplikasi Anda, menghilangkan pekerjaan pemeliharaan dan mengurangi biaya. Bagi para engineer kami, kualitas dan keamanan komponen, yaitu ketahanan dan masa pakai, merupakan kriteria penting dalam pengembangan. Setiap produk igus® diuji secara ekstensif sebelum dijual. Kami telah mengoperasikan laboratorium pengujian kami sendiri untuk tujuan ini sejak tahun 1985. Laboratorium ini tidak hanya yang terbesar di industri untuk tribopolimer dalam hal luas permukaan, tetapi juga yang memiliki jumlah pengujian produk dan prosedur pengujian tertinggi - dan oleh karena itu menjadi dasar jaminan kami hingga 4 tahun.

Halaman ini menawarkan detail berikut mengenai laboratorium uji kami

Apa yang diuji?

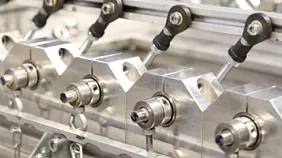

Area uji coba aplikasi dan material kami mencakup lebih dari 5.500 m². Setiap unit bisnis memiliki laboratorium uji coba sendiri, dan beberapa area produk diuji bersama:

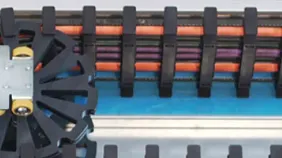

- 2.000 m² area luar ruangan untuk energy chain dan kabel chainflex® dengan jarak lintasan yang sangat panjang

- 1.500 m² area pengujian untuk kabel chainflex® dalam energy chain kami sendiri

- 300 m² area uji untuk iglidur® plain bearings, drylin® linear bearings dan Low Cost Automation - yang terakhir sebagian di bawah kondisi nyata dalam jaminan kualitas

- 200 m² area uji untuk igus:bike® dan komponen sepeda

- BARU: Area uji 1.500 m² di gedung pabrik baru

Agar dapat mengembangkan produk baru yang kompatibel dengan ruang bersih secara lebih cepat, kami mengoperasikan laboratorium ruang bersih kami sendiri dengan sistem ruang bersih ISO kelas 1 yang bekerja sama dengan Fraunhofer IPA. Area pengujian di luar ruangan, laboratorium untuk pengujian kebisingan dan ruang iklim pada suhu -40° C, yang dikhawatirkan oleh karyawan igus®, melengkapi area pengujian kami. Untuk realisme maksimum, kami juga menguji aplikasi pelanggan dan melakukan pengujian industri.

.

Kami juga menguji aplikasi Anda

Anda tidak ingin bereksperimen dan menguji aplikasi Anda dengan uji material sebelum digunakan? Atau apakah Anda memiliki aplikasi yang tidak biasa yang membutuhkan komponen yang sesuai? Tidak masalah! Kami akan menguji aplikasi Anda di laboratorium pengujian kami dan menggunakan keahlian kami untuk menemukan solusi igus® yang terbaik untuk Anda. Baik plain bearing, energy chain®, cable, linear technology, bar stock or Low Cost Automation.

.

Berapa banyak pengujian yang dilakukan di laboratorium igus®?

Setiap tahun, sejumlah besar pengujian dan tes material dilakukan pada 742 sistem pengujian kami:

- Lebih dari 15.000 pengujian secara keseluruhan, termasuk sekitar 4.000 pengujian pada e-chain® dan chainflex® dan sekitar 11.000 pengujian pada dry-tech® (berotasi, berputar, linear, berjalan, dipanaskan, di bawah air, dll.).

- 10 miliar siklus e-chain®

- 3.500 kabel yang telah diuji

- 1.000 pengujian yang disesuaikan

- Hingga 800 pengujian paralel

.

Apa yang terjadi pada data pengujian?

Penggunaan data dari prosedur pengujian tidak berhenti setelah pengembangan. Sejak tahun 2001, kami telah mengembangkan alat bantu online yang inovatif dan, sejak tahun 2016,smart plastic berbasis sensor berdasarkan basis data hasil laboratorium uji kami. Dengan alat ini, efektivitas biaya dan keamanan produk kami dapat ditentukan dengan mudah, cepat, dan sepanjang waktu secara online. Hal ini memberikan transparansi tingkat tinggi kepada pelanggan kami dan memungkinkan mereka untuk menemukan solusi fungsional yang hemat biaya untuk masalah mereka. Lebih dari 40 alat tersedia untuk Anda secara gratis, termasuk kalkulator masa pakai, konfigurator untuk perbandingan produk, pencari produk, konfigurator produk, dan konfigurator CAD, serta pemeliharaan prediktif kami dengan i.Cee.

.

Jelajahi tur virtual laboratorium

Apakah Anda ingin melihat-lihat laboratorium kami? Tidak masalah: Anda dapat menjelajahi semua area dari kenyamanan rumah atau kantor Anda sendiri melalui tur virtual. Cukup klik tombol di bawah ini, pilih area laboratorium yang diinginkan di halaman awal dan ikuti panah ke titik tampilan berikutnya. Klik pada nomor untuk mengetahui lebih lanjut tentang produk yang diuji.