Ubah Bahasa :

drylin® T - Aturan desain

Tip desain

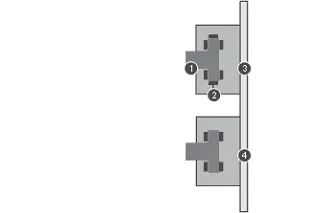

Versi dengan bantalan mengambang dalam arah-z

Kompensasi kesalahan paralelisme antara rel yang dipasang dimungkinkan dengan bantalan tetap/terapung dalam kisaran hingga maksimum 0,5 mm. Selama pemasangan, penting untuk memastikan bahwa bantalan apung memiliki jarak bebas yang kurang lebih sama di kedua arah.

Desain sistem bantalan lokasi/non-lokasi yang kami rekomendasikan dapat dilihat pada ilustrasi di samping.

Permukaan sambungan untuk rel dan gerbong harus memiliki kerataan yang baik (mis. permukaan yang digiling) untuk menghindari ketegangan dalam sistem. Ketidakrataan kecil pada permukaan sambungan dapat dikompensasi secara individual hingga tingkat tertentu (0,5 mm) dengan menyesuaikan jarak bebas ke nilai yang lebih besar. Penyesuaian jarak bebas hanya dapat dilakukan dalam keadaan tanpa muatan.

Jika Anda memiliki pertanyaan mengenai desain dan/atau pemasangan, silakan hubungi konsultan aplikasi kami.

1

rel

2

Elemen geser

3

Kereta bantalan tetap

4

Kereta bantalan mengambang LLZ atau LLY

floating bearing untuk sistem pemandu

Penyetaraan otomatis kesalahan paralelisme,

Floating bearing pertama, fixed bearing yang kedua

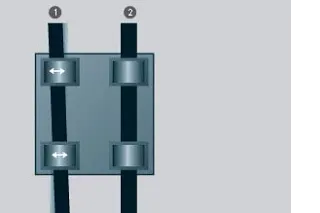

Saat menggunakan sistem dengan dua pemandu paralel, satu sisi harus dirancang sebagai floating bearing. Ada solusi bearing lokasi/non-lokasi yang sesuai untuk setiap posisi pemasangan, baik horizontal, vertikal, maupun lateral. Metode pemasangan ini mencegah kekakuan atau kemacetan pemandu jika terjadi penyimpangan paralelisme di antara pemandu. Floating bearing direalisasikan dengan perpanjangan clearance yang terkontrol ke arah kesalahan paralelisme yang di antisipasi. Hal ini menciptakan tingkat kebebasan tambahan di satu sisi.

Selama pemasangan, penting untuk memastikan bahwa floating bearing memiliki clearance yang kurang lebih sama di kedua arah. Desain sistem bearing lokasi / non-lokasi yang kami rekomendasikan dapat ditemukan dalam ilustrasi di masing-masing bab sistem. Permukaan sambungan untuk pemandu dan carriage harus memiliki kerataan yang baik (mis. Permukaan yang digiling) untuk menghindari ketegangan dalam sistem. Ketidakrataan yang kecil pada permukaan sambungan dapat dikompensasi sampai batas tertentu dengan floating bearing.

Kekuatan eksentrik

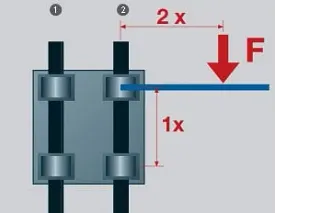

Aturan 2:1,

floating bearing pertama, fixed bearing yang kedua

Beberapa rekomendasi harus diperhatikan untuk keberhasilan penggunaan drylin® linear bearing yang bebas perawatan: Jika jarak antara gaya penggerak dan fixed bearing lebih dari dua kali jarak bearing (aturan 2:1), koefisien gesekan statis 0,25 secara teoritis menyebabkan macetnya pemandu.

Prinsipnya tidak bergantung pada beban atau gaya penggerak. Ini adalah produk dari gesekan dan selalu berhubungan dengan bearing lokasi. Semakin jauh drive dari bearing pemandu, semakin besar keausan dan gaya penggerak yang diperlukan.

Jika aturan 2: 1 tidak diperhatikan saat menggunakan linear plain bearing, hasilnya adalah gerakan yang tidak rata atau bahkan pemblokiran sistem. Hal ini sering kali dapat diatasi dengan modifikasi yang relatif sederhana.

Jika Anda memiliki pertanyaan tentang desain dan / atau pemasangan, silakan hubungi konsultan aplikasi kami.

Konsultasi

Saya akan dengan senang hati menjawab pertanyaan Anda secara langsung

Pengiriman dan konsultasi

Secara pribadi:

Senin - Jumat dari jam 8.30 - 17.30 WIB

Online:

24 Jam

WhatsApp-Service:

Senin - Jumat dari jam 8.30 - 17.30 WIB